Drone Materials Guide: Choose the Most Durable …

In This Article

- Material choice directly impacts drone durability, weight, and lifespan.

- Carbon fibre leads in strength-to-weight, but at a higher cost and brittle nature.

- Aluminium provides robustness and thermal management, ideal for rugged use.

- Composites and plastics strike affordable balances for beginners and casual users.

- Match your materials to your drone’s operating environment and purpose.

Understanding Drone Frame Structures

Why Frame Design Matters

The structure of a drone forms the skeletal framework upon which all other components are mounted. This includes arms, landing gear, body casing, and mounts for propellers or motors. The durability and flight efficiency of a drone hinge largely on the quality and type of materials used in its construction. Specific drone materials affect the airframe’s rigidity, resistance to vibration, and ability to withstand impact during flight or rough landings. Without a solid structural foundation, even the most sophisticated sensors and control systems can fail. Consequently, drone manufacturers and custom-build enthusiasts put considerable thought into how frame design interacts with material choice to ensure durability, balance, and optimal performance.

Types of Drone Materials Used Today

From Plastics to Composites

Modern drone materials vary significantly based on use-case, ranging from entry-level plastic frames to high-end composite builds used in enterprise-level aviation. Basic drones often utilise acrylonitrile butadiene styrene (ABS) plastics due to their low cost and ease of moulding. These are preferred for educational kits or toys but are prone to cracking upon impact. On the other hand, polycarbonate is tougher and more flexible, often found in mid-tier drones. Advanced drones increasingly rely on composite materials—particularly carbon fibre and glass fibre composites—for superior stiffness, reduced weight, and enhanced impact resistance. Each of these options offers a different balance of weight, flexibility, strength, and cost which can dramatically influence the final product’s resilience in flight.

As the industry matures, designers are also incorporating hybrid frames combining metals such as aluminium with carbon fibre to harness the strengths of both materials. Innovations in 3D printing have further diversified available resources, allowing the integration of lightweight thermoplastics with carbon reinforcements. All these developments underscore the importance of understanding how each material behaves under stress, exposure, and repetitive movement to design drones that can endure long-term use.

“Drone durability starts with the materials you choose—decisions at the component level can determine mission-critical reliability.”

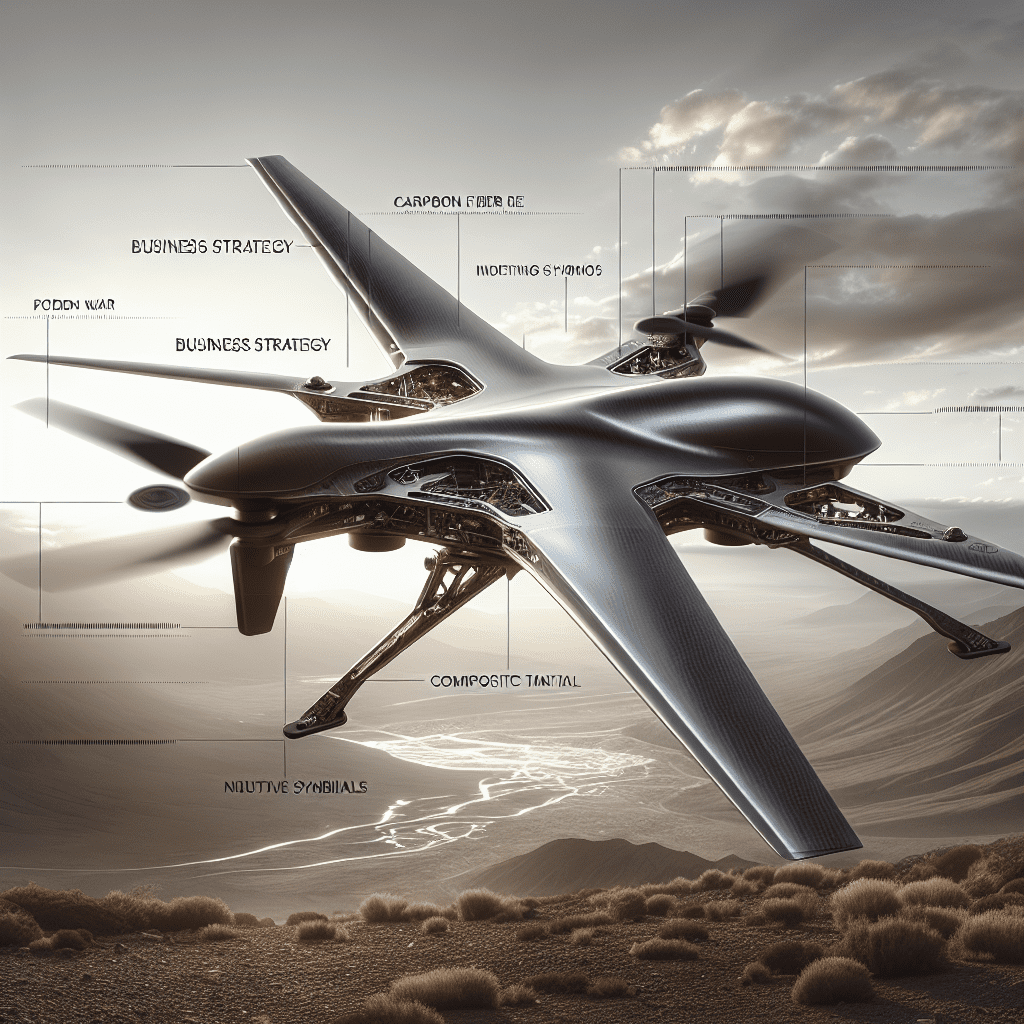

Carbon Fiber: The Gold Standard

Carbon fibre has emerged as the benchmark in premium drone materials. Known for its unmatched strength-to-weight ratio, carbon fibre comprises thin strands of carbon woven into a fabric and set in a resin matrix. This combination delivers incredible rigidity and structural integrity without the weight penalty of metals. The rigidity of carbon fibre ensures minimal deformation, which is crucial for high-speed and heavy-lift drones, where flight stability and control accuracy are non-negotiable. It also dampens vibrations that could negatively affect sensors and camera footage.

Another key benefit lies in carbon fibre’s resistance to corrosion and ultraviolet degradation. Whether operating in coastal regions or under intense sunlight, drones built with carbon fibre exhibit greater longevity. Although carbon fibre is relatively more expensive than plastic or aluminium, its advantages in performance and resilience justify the investment, especially in commercial or competitive drone applications.

However, carbon fibre does have a brittleness under extreme impact, which can lead to sudden failure rather than deformation. For this reason, it’s often preferred with protective layering or blended into hybrid frameworks to enhance shock resistance.

Comparing Aluminum and Composite Alternatives

Aluminium remains a highly regarded option for drone frames due to its widespread availability, ease of machining, and natural oxidation resistance. Aluminium alloys, particularly 6061 and 7075, offer a respectable compromise between strength and weight. These are often employed in the arms and mounts of drones for rigidity and heat dissipation. Additionally, aluminium provides excellent thermal conductivity, useful for drones with powerful motors that generate significant heat.

That said, aluminium is heavier than carbon composites and is prone to bending under repetitive mechanical stress. It might not be ideal for ultra-light racing drones or long-range aerial photography units, but it presents a reliable choice for rugged drones designed to withstand crashes or heavy-duty operations. On the other hand, composite materials like glass fibre—though not as strong as carbon fibre—offer increased flexibility and reduced cost, making them perfect for beginner or hobbyist drone builds.

Impact Resistance Across Materials

Impact resistance is a critical performance variable when it comes to drone durability. Drones often encounter unpredictable wind conditions, unexpected obstacles, and hard landings. Here, drone materials dramatically influence the outcome of these encounters. Plastics, for example, tend to absorb minor impacts effectively, flexing before breaking—but fail under severe strain. Carbon fibre, with its rigidity, tends to shatter when the impact threshold is exceeded, revealing its inherent brittleness under specific conditions.

Aluminium deforms rather than fractures, providing a built-in warning of potential failure points. This bend-before-breakability allows for potential field repairs, which is why aluminium remains popular in modular drone designs. For drones deployed in rescue, military, or exploratory missions where retrieval might be delayed, robust impact resistance could mean the difference between mission success and failure.

Corrosion and Weatherproofing Considerations

Exposure to elements such as moisture, salt, heat, and wind can severely degrade drone materials over time. Metals like aluminium, though naturally resistant to rust through passivation, can corrode in extremely saline conditions without protective anodising. Carbon fibre resists corrosion better but is susceptible to galvanic corrosion when in contact with specific metals.

Plastics are generally immune to corrosion but may degrade under prolonged UV exposure, becoming brittle and discoloured. Selecting materials that withstand environmental stressors is paramount for professional use cases—search and rescue, agriculture, and environmental monitoring often expose drones to harsh weather which necessitates highly durable, non-reactive materials. Most premium drones include coated or treated components to reduce such long-term wear. Design engineers must pay attention to the interplay between structural strength and resistance to environmental decay when choosing the appropriate drone materials.

Weight vs. Strength Trade-Offs

Balancing weight and strength is one of the most trifle yet essential tasks in drone design. Materials like carbon fibre optimise this balance, offering exceptional tensile strength for their weight. In contrast, while aluminium is stronger in its raw form, its heavier profile may negatively affect flight time and agility.

For applications like racing drones or long-duration aerial surveys, keeping the frame as light as possible enhances battery efficiency and manoeuvrability. On the other hand, for industrial drones carrying payloads such as LiDAR or agricultural sensors, extra frame strength might take precedence over extended air-time. Integrating reinforcements in stress-prone areas and using lightweight components elsewhere allows for strategic material deployment without performance compromise.

Cost Efficiency for Builders and Beginners

Budget remains a significant constraint for many drone builders, especially beginners or educational institutions. Here, less-expensive materials like ABS plastic or lightweight aluminium provide an accessible entry point. While these may not offer the same performance metrics as carbon fibre or technical composites, they reduce the stakes for experimentation and basic training exercises.

For builders seeking cost efficiency without sacrificing too much quality, hybrid solutions—such as combining polycarbonate with carbon fibre-braced arms—can strike a fine balance. Open-source drone kits also provide modular frameworks that can be upgraded later with better materials. Utilising third-party suppliers and keeping abreast of material innovations are essential practices for fiscally responsible builders.

Material Selection by Drone Use-Case

Different types of drones necessitate unique material profiles, tailored to specific functional goals. Aerial photography drones demand lightweight but corrosion-resistant materials to ensure longer flight durations and high-altitude performance. Carbon fibre typically serves this role well. Racing drones, different in focus, require materials capable of withstanding rapid propulsion and intermittent collisions—strong plastics and mixed composites excel here.

Delivery drones, slated to carry heavier payloads, often benefit from aluminium frames reinforced with carbon fibre joints for strength and reduced cost. Meanwhile, military and surveillance drones prioritise stealth and thermal resistance—resulting in the use of advanced ceramics and highly engineered composite blends.

In agriculture, drones must battle dust, moisture, and knocks—making impact-resistant but repair-friendly materials like reinforced polymers highly suitable. Choosing drone materials based on application is critical to functionality, longevity, and safety.

Tips for Choosing the Right Materials

Before settling on drone materials, ask what kind of missions your drone will carry out. Will it endure constant travel, or will it fly occasionally? Is portability essential? Will it operate in extreme heat or salt-laden air? Considering the drone’s operational context ensures material relevance and longevity.

Conduct performance simulations or consult structural engineers if you’re involved in commercial or industrial-grade builds. Invest in modular parts, allowing you to swap frame arms or replace broken components without binning the entire structure. Always prioritise compatibility with your flight controller and motor setup. Maintaining harmony between physical structure and internal electronics prevents vibration-induced failures.

In every case, the key is to see drone materials not in isolation but as part of an interdependent system optimised for endurance, efficiency, and mission success. Beginners can benefit from community forums for material reviews and shared test data—resources available via Learn more about Drone Materials & Engineering and Read a related article.

Conclusion: Designing for Durability

[CONCLUSION_CONTENT]

Great guide on master-drone-durability-choosing-the-right-materials – Community Feedback

What is the best material for a drone frame?

Carbon fiber is widely regarded as the best due to its high strength-to-weight ratio and excellent durability, though aluminum and reinforced plastics are also popular for specific needs.

How do materials affect a drone’s flight performance?

Heavier materials may reduce flight time but offer more durability, while lightweight composites enable longer flights but may be less impact-resistant.

Are composite materials necessary for high-performance drones?

Yes, composites like carbon fiber are essential for achieving both lightweight build and structural strength in advanced drones.