Understanding Drone Materials

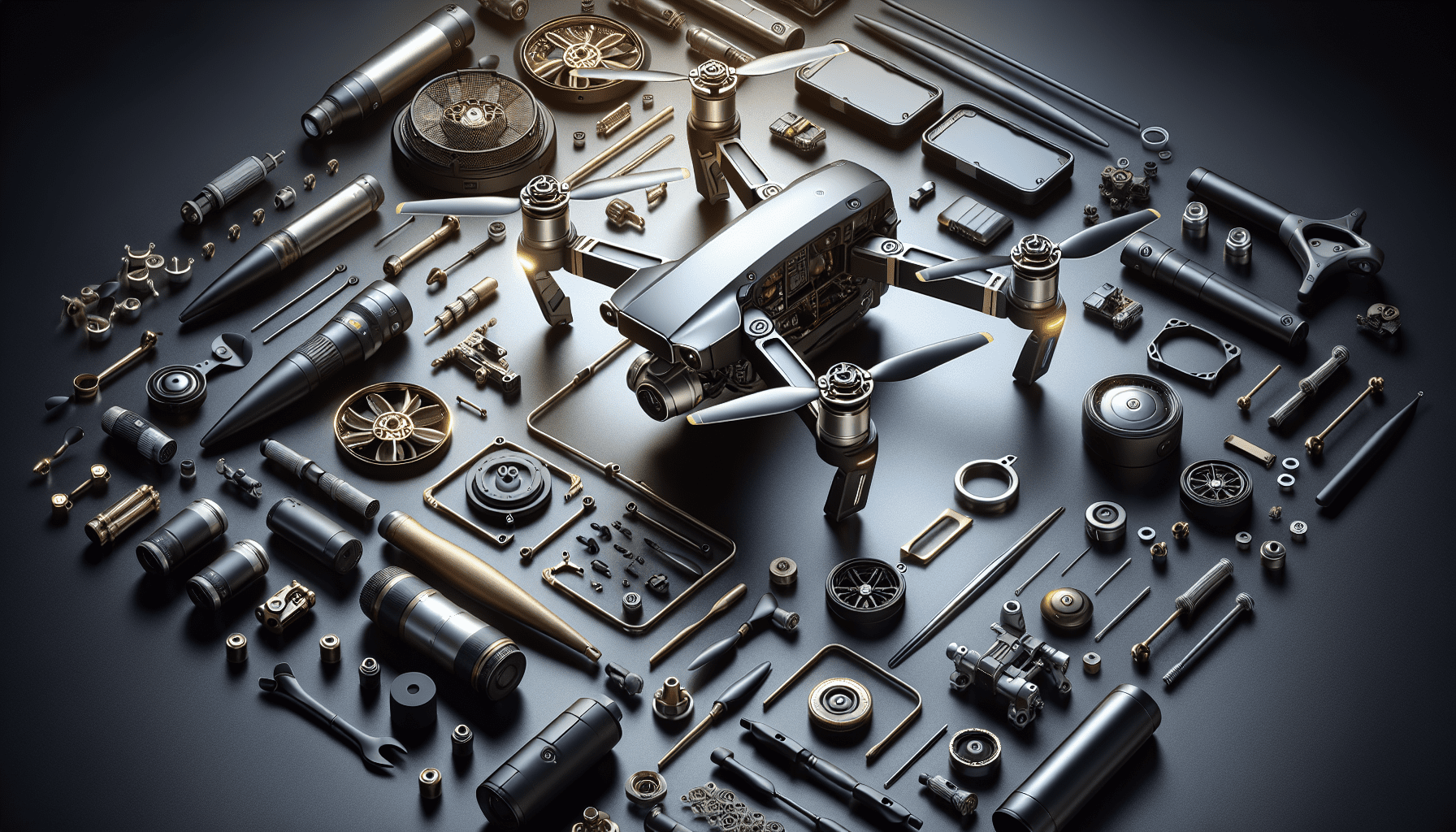

The term drone materials encompasses a wide range of substances used in the construction of drones. Primarily, these materials can be grouped into three main categories: plastics, metals, and composites. Each category has its unique attributes affecting performance, cost, and vulnerability to environmental factors. By breaking down these categories, we can gain a clearer insight into how the choice of materials affects a drone’s survivability against the elements and other stresses encountered during operations.

1. Plastics: Lightweight and Versatile

Plastics are among the most used drone materials, significantly due to their lightweight nature and versatility. Commonly used plastics like Acrylonitrile Butadiene Styrene (ABS) or Polycarbonate (PC) provide a substantial balance between durability and weight. They are not only resistant to corrosion but also provide excellent impact resistance. This makes them ideal for entry-level drones, particularly those intended for recreational use. However, while plastics offer much in terms of flexibility in design, they also tend to lack the rigidity that metal materials can provide, which may compromise structural integrity over time.

2. Metals: Strength and Reliability

Metals such as aluminium and titanium are renowned for their strength-to-weight ratios and contribute greatly to the durability of high-performance drones. Aluminium is typically lightweight yet robust, which allows it to withstand various environmental challenges without adding excessive weight. For circumstances requiring greater toughness, titanium is often employed despite its higher cost. Its superior strength and resistance to fatigue make it a favourite for tactical UAVs (Unmanned Aerial Vehicles) or those designed for industrial applications.

3. Composites: The Best of Both Worlds

Composites represent a significant advancement in drone materials, combining elements of both plastic and metal to create strong yet lightweight structures. Common composites include carbon fibre and glass fibre, both of which provide impressive strength while being significantly lighter than their metal counterparts. The ability of composites to withstand high-stress scenarios while maintaining a light profile makes them ideal for professional drones used in filmmaking, surveying, or search and rescue operations. Nevertheless, working with composites can be more complex and expensive, leading to considerations around repairability and manufacturing processes.

Evaluating Durability: Key Factors

When evaluating the durability of various drone materials, several key factors must be considered. Among these factors, tensile strength, impact resistance, and environmental resilience rank highly. Each of these attributes contributes substantially to how well a drone can withstand various stresses and strains during operation.

“The choice of materials can either optimise or severely limit a drone’s operational performance.”

Tensile Strength

Tensile strength refers to the resistance of a material to being pulled apart and is essential in maintaining the structural integrity of drones during flight. For instance, drones constructed from aluminium and titanium exhibit significant tensile strength, enabling them to endure adverse conditions without succumbing to deformation. In contrast, some plastics, while lightweight, may not possess the same level of tensile strength, making them more prone to warping under stress.

Impact Resistance

The impact resistance of drone materials is crucial, especially for drones used in environments where collision with objects is a possibility. Materials like carbon fibre and reinforced plastics can absorb shocks without significant damage, while metals can dent or bend but generally maintain their structural capabilities. A drone designed for rugged terrain or urban environments must incorporate materials that can withstand significant impacts without failing.

Environmental Resilience

Environmental factors can heavily influence the longevity and durability of drone materials. Exposure to elements such as moisture, UV radiation, and temperature fluctuations can degrade materials over time. For example, certain plastics may become brittle in cold temperatures and lose structural integrity when exposed to UV light. Conversely, materials such as composites include components that can withstand these conditions, making them more suitable for outdoor operations where weather exposure is inevitable.

Case Studies: Material Composition in Action

Examining real-world case studies provides valuable insights into the practical applications and durability of various drone materials. Companies have consistently chosen differing materials based on the operational requirements of their drones, which has yielded fascinating results.

Case Study 1: Commercial Drone for Filming

A notable case in the commercial film industry involves a drone equipped with a carbon fibre frame. The filmmakers required a lightweight yet strong structure to house high-end camera equipment. By using carbon fibre, the drone could achieve high performance in aerial shots while remaining agile. This combination allowed for longer flight times and stable shoots that were otherwise difficult to capture with heavier drones. The decision to employ composite materials paid off, as the drone showed minimal wear even after prolonged usage in diverse conditions.

Case Study 2: Industrial Surveying Drone

In the industrial sector, a leading surveying company utilised a titanium-framed drone for its rugged durability. Engaging in structural inspections in harsh environments meant the drone faced significant risks from strong winds and varying temperatures. The choice of titanium ensured that the drone not only maintained its integrity but also lasted significantly longer than its aluminium counterparts. Given the expense associated with maintaining and replacing equipment, employing a robust material like titanium proved economically viable.

The Future of Drone Materials

As advancements in technology continue, the future of drone materials looks promising. Researchers are experimenting with new alloys and composites aimed at enhancing durability, lowering weight, and reducing costs. Innovations such as self-healing materials may soon enter the market, drastically changing the approach to durability in drone design.

Innovations in Material Science

The ongoing development in material science suggests that future drones could increasingly favour advanced materials that not only withstand environmental pressures but also reduce overall energy consumption. Materials that offer thermal insulation or improved aerodynamics will become paramount as drone applications expand into diverse sectors from agriculture to humanitarian efforts. The focus will shift towards intelligent materials that can adjust to their environment, greatly extending the functionality and lifespan of drones.

Maximising Durability

Ultimately, the choice of drone materials will play a crucial role in maximising durability. Manufacturers will need to balance several considerations, including cost, weight, and operational requirements when selecting materials. Proactive research into the long-term performance of these materials under real-world conditions will be vital for making informed decisions that enhance the durability of drones.

Conclusion: The Importance of Material Selection

The composition of a drone’s materials is far more than a technical specification; it plays a vital role in operational success and longevity. By comparing the various materials—plastics, metals, and composites—we gather invaluable insights into how these choices affect durability and performance. As technology progresses, the significance of innovative materials will become increasingly pronounced, offering new possibilities for drone design and functionality. With the right material selection, whether for a simple hobbyist drone or an advanced industrial model, operators can ensure durability, performance, and ultimately, satisfaction. Explore our range of durable drones and see the difference in performance and longevity.

Frequently Asked Questions

What materials make a drone durable?

- Drones are typically made from lightweight yet strong materials like carbon fiber, plastic composites, and aluminum, which contribute to their durability.